Kia Picanto (JA): ISG (Idle Stop & Go) System / AGM Battery

Specifications

▷ AGM50L-DIN

Item

|

Specification

|

Capacity [20HR / 5HR] (AH)

| 50/40

|

Cold Cranking Amperage (A)

| 560 (SAE) / 560(EN)

|

Reserve Capacity (Min)

| 80

|

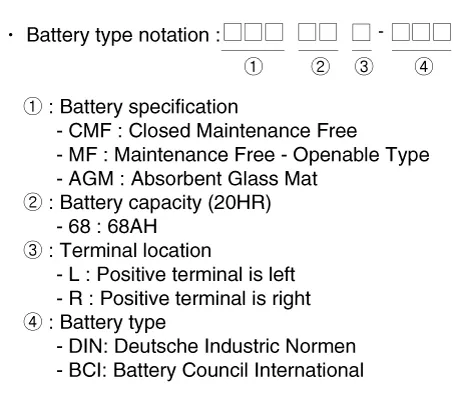

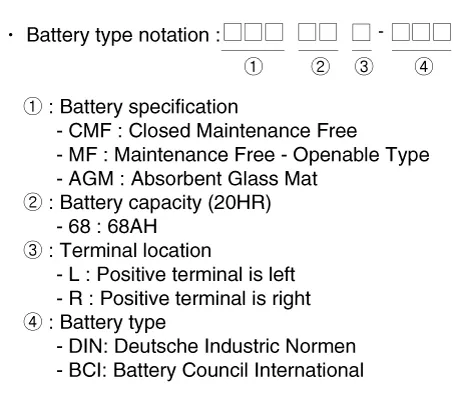

| •

| Model type description

|

| •

| Cold

Cranking Ampere (CCA): Cold Cranking Amps is a rating used in the

battery industry to define a battery's ability to start an engine in

cold temperatures. |

| –

| The

rating is the number of amps a new, fully charged battery can deliver

at -18 °C(-0.4 °F) for 30 seconds, while maintaining a voltage of at

least 7.2 volts for a 12 volt battery. |

| –

| The higher the CCA rating, the greater the starting power of the battery. |

| •

| RESERVE

CAPACITY (RC) : Reserve Capacity is a battery industry rating, defining

a battery's ability to power a vehicle with an inoperative alternator

or fan belt. |

| –

| The

rating is the number of minutes a battery at 26.7 °C(80 °F) can be

discharged at 25 amps and maintain a voltage of 10.5 volts for a 12 volt

battery. |

| –

| The higher the reserve rating, the longer your vehicle can operate should your alternator or fan belt fails. |

|

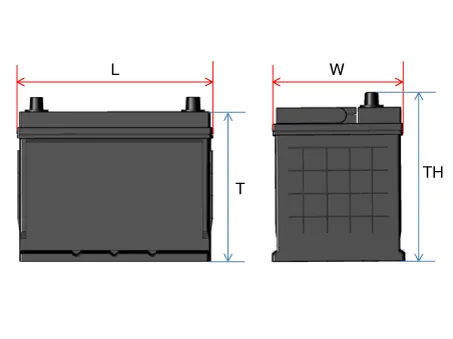

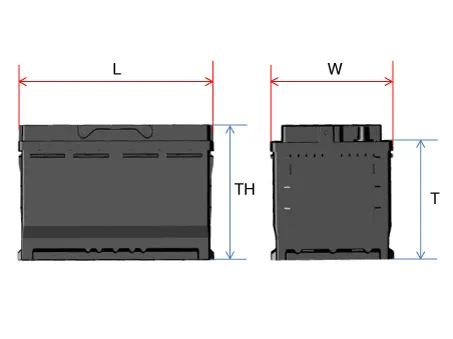

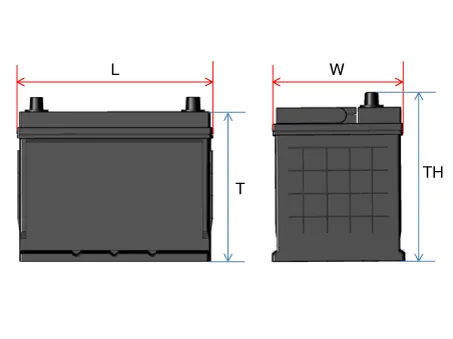

BCI Type

Capacity

(5 hr/20 hr)

|

Length

|

Width

|

Height

|

Total Height

|

L (mm)

|

W (mm)

|

H (mm)

|

TH (mm)

| 28/35

| 188 - 192

| 126 - 130

| 198 - 202

| 218 - 222

| 32/40

| 194 - 198

| 133 - 137

| 199 - 203

| 223 - 227

| 36/45

| 203 - 207

| 173 - 177

| 200 - 204

| 221 - 225

| 44/55

| 213 - 217

| 173 - 177

| 198 - 202

| 218 - 222

| 48/60

| 228 - 232

| 173 - 177

| 200 - 204

| 221 - 225

| 54/68

| 258 - 262

| 173 - 177

| 198 - 202

| 220 - 224

| 56/70

| 258 - 262

| 173 - 177

| 198 - 202

| 223 - 227

| 64/80

| 274 - 278

| 170 - 174

| 198 - 202

| 221 - 225

| 70/88

| 349 - 353

| 172 - 176

| 186 - 200

| 183 - 187

| 72/90

| 300 - 304

| 170 - 174

| 200 - 204

| 221 - 225

| 76/95

| 294 - 298

| 172 - 176

| 198 - 202

| 220 - 224

| 80/100

| 326 - 330

| 170 - 174

| 203 - 207

| 225 - 229

|

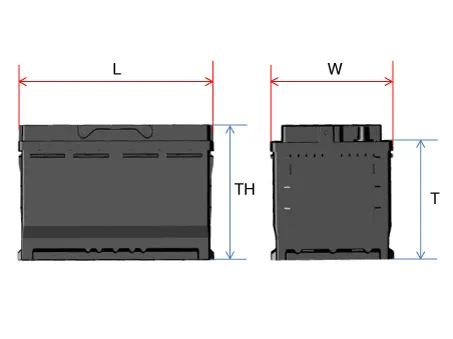

DIN Type

Capacity

(5HR/20HR)

|

Length

|

Width

|

Height

|

Total Height

|

L (mm)

|

W (mm)

|

H (mm)

|

TH (mm)

| 36/45

| 205 - 207

| 173 - 175

| 164 - 168

| 188 - 190

| 48/60

| 205 - 207

| 173 - 175

| 164 - 168

| 188 - 190

| 54/68

| 205 - 207

| 173 - 175

| 164 - 168

| 188 - 190

| 64/80

| 205 - 207

| 173 - 175

| 164 - 168

| 188 - 190

| 72/90

| 205 - 207

| 173 - 175

| 164 - 168

| 188 - 190

| 80/100

| 205 - 207

| 173 - 175

| 164 - 168

| 188 - 190

| 88/110

| 205 - 207

| 173 - 175

| 164 - 168

| 188 - 190

|

AGM DIN Type

Capacity

(5HR/20HR)

|

Length

|

Width

|

Height

|

Total Height

|

L (mm)

|

W (mm)

|

H (mm)

|

TH (mm)

| 40/50

| 205 - 207

| 173 - 175

| 164 - 168

| 188 - 190

| 48/60

| 227 - 229

| 173 - 175

| 164 - 168

| 188 - 190

| 56/70

| 276 - 278

| 173 - 175

| 164 - 168

| 188 - 190

| 64/80

| 312 - 314

| 173 - 175

| 164 - 168

| 188 - 190

| 72/90

| 351 - 353

| 173 - 175

| 164 - 168

| 188 - 190

| 84/105

| 392 - 394

| 173 - 175

| 164 - 168

| 188 - 190

|

|

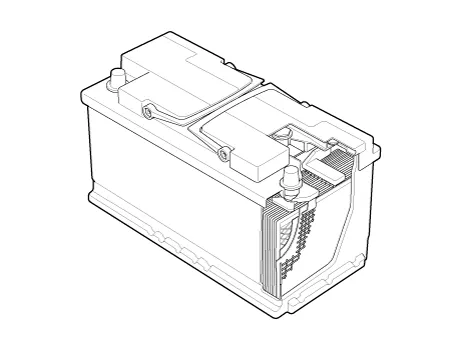

Description and operation

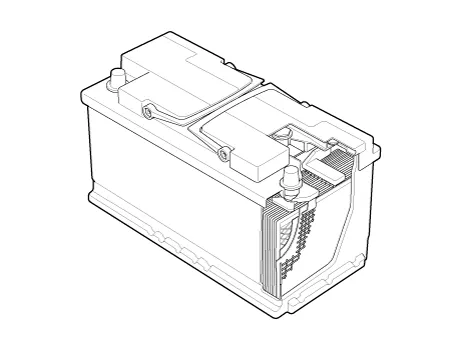

| [AGM Battery for ISG System] |

AGM

battery is used for especially heavy load on the vehicle network

depending on equipment and requirements. AGM stands for Absorbent Glass

Material Battery, which is absorbent glass fibre fleece. AGM batteries

are fitted to models with high electrical loads or for consumer with

high energy demand.

The constantly increasing energy demand of modern vehicle electrical systems calls for ever more powerful battery solutions.

The power consumption is considerably high even when the vehicle is partked.

The somewhat higher price compared with a battery of similar size is fully balanced by the following benefits:

| –

| Significantly longer service life |

| –

| Increased starting reliability at low temperatures |

| –

| 100% free from maintenance |

| –

| Low risk in the event of an accident (reduced risk to the environment) |

Recharging the AGM battery

The battery can be charged by using a battery charger with a constant charging voltage of 14.8 V.

If possible, keep the battery temperature between 20°C (68°F) and 30°C (86°F) during charging.

Only chargers with voltage clamping (IU or WU curve) or chargers with IUoU curve capable of trickle charge can be used.

IU or WU charging technique

Optimized charging voltage for IU or WU: 14.7 V (at 20°C - 30°C (68°F - 86°F)) for about 24 hours Min. charging voltage at 20°C (68°F): 14.4 V Max. charging voltage at 20°C (68°F): 14.8 V 10% of capacity is recommended as charging current (e.g. 60 Ah : 10 = 6.0 A charging current). |

| •

| Do not charge an AGM battery with voltage greater than 15.2 V. Do not quick charge the AGM battery. |

|

| •

| If

the battery is charged directly at the battery terminals on vehicles

with battery sensor, misinterpretations of battery condition may occur,

and under certain circumstances, unwanted 'Check Control' message or

faulty memory can be prompted. When recharging is finished, let the battery stand for over 10 hours at normal temperature for battery stabilization. |

|

Repair procedures

Battery

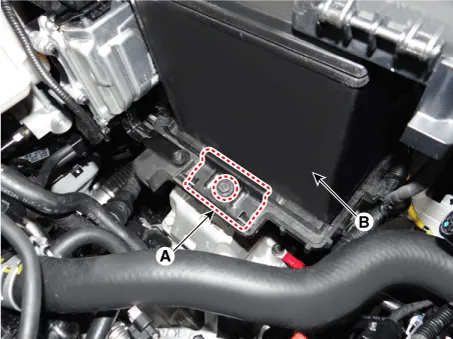

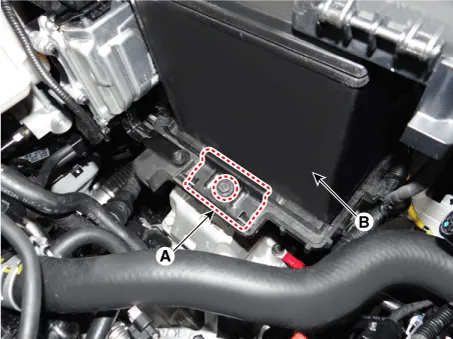

| 1. | Turn the ignition switch OFF. |

| 2. | Disconnect the battery negative (-) terminal (A).

|

| 3. | Disconnect the battery positive (+) terminal (A).

|

| 4. | Remove the battery mounting bracket (A) after loosening the mounting bolt. |

| 5. | Remove the battery (B).

|

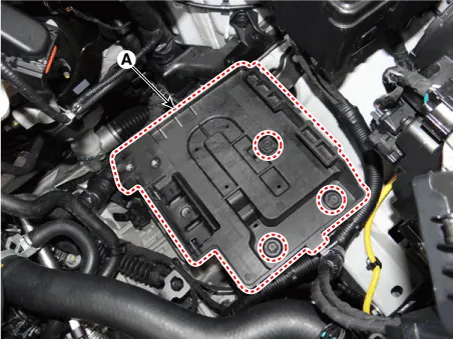

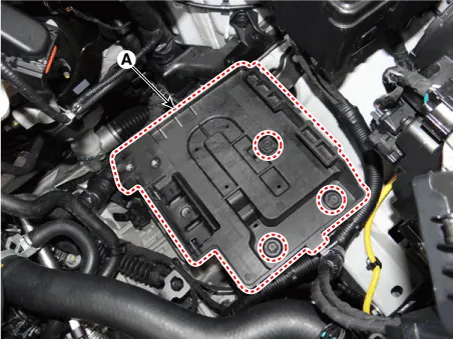

Battery tray

| 1. | Remove the battery.

(Refer to Charging System - "Battery")

|

| 2. | Remove the ECM.

(Refer to Engine Control / Fuel System - "Engine Control Module (ECM)")

|

| 3. | Remove the battery tray (A) after loosening the mounting bolts.

|

| 1. | Install in the reverse order of removal. | •

| When installing the battery, fix the mounting bracket on the tray correctly. |

|

| •

| After disconnecting then reconnecting the battery negative cable, reset some parts that require the reset procedures.

(Refer to Body Electrical System - "General Information")

|

|

| •

| When installing the battery, fix the mounting bracket on the tray correctly. |

|

| •

| ISG

(Idle stop & go) system equipped vehicle uses the AGM battery only.

Installing a flooded battery may potentially lead to engine electrical

trouble or ISG system error. |

| •

| Replace with an AGM battery of the same capacity. |

|

| •

| Ensure that an AGM battery is fitted. |

| •

| In all cases, an AGM battery must be installed and registered in the vehicle for the ISG function to work perfectly. |

| •

| After

replacing with a new battery, the vehicle must stand for at least 4

hours with the ignition switch OFF, doors closed and hood switch OFF. |

| •

| ISG system stabilization may take 4 hours after installing a new battery. |

| •

| After standing for 4 hours, the ISG function will operate with 2 cranks by the user. However,

for the first 25 times, the ISG function can operate regardless of ISG

system stability for ISG function operation check. |

|

| •

| Do not open the AGM battery. The

AGM battery must not be opened under any circumstances as the

introduction of oxygen from the air will cause the battery to lose its

chemical equilibrium and become non-operational. |

|

|

Battery charging

In general, vehicle battery charging system has three forms.

| 1. | Constant

current charge: The battery voltage gradually rises by charging at a

constant current setting. If charging current and time are not managed

correctly, the battery may be overcharged. Therefore, stop charging

after confirming the completion of charging. | –

| General charge: Charging the battery for a long time with low current |

| –

| Quick charge: Charging the battery for a short time with high current |

|

| 2. | Constant voltage charge: The battery charging current gradually reduces by charging at a constant voltage setting. |

If

the battery is charged directly at the battery terminals on vehicles

with battery sensor, misinterpretations of battery condition may occur,

and under certain circumstances, unwanted 'Check Control' message or

faulty memory can be prompted. When recharging is finished, let the battery stand for over 10 hours at normal temperature for battery stabilization. |

Battery Voltage and Status

Check the battery voltage and status by using a battery tester.

Battery Terminal

| 1. | Move back and forth to check if the battery terminals (A) are loose or corroded. Clean any corroded terminals.

If

the battery positive connection is loose, disconnect the ground (GND)

cable first before attempting to remove or tighten the positive

connection to prevent personal injury. |

| 2. | If the battery clamp on positive (+) battery terminal is not seated securely: | (1) | Turn ignition switch OFF and disconnect the negative (-) battery terminal. |

| (2) | Tighten battery clamp (A) on positive (+) battery terminal.

Positive (+) battery terminal:

7.8 - 9.8 N·m (0.8 - 1.0 kgf·m, 5.8 - 7.2 lb·ft) |

|

|

| 3. | If the battery clamp on negative (-) battery terminal is not seated securely: | (1) | Tighten battery clamp (A) on negative (-) battery terminal.

Negative (-) battery terminal:

4.0 - 6.0 N·m (0.4 - 0.6 kgf·m, 3.0 - 4.4 lb·ft) |

|

|

Battery Condition

Check the battery for damage or deformation. If severe damage, deformation or leakage is found, replace the battery.

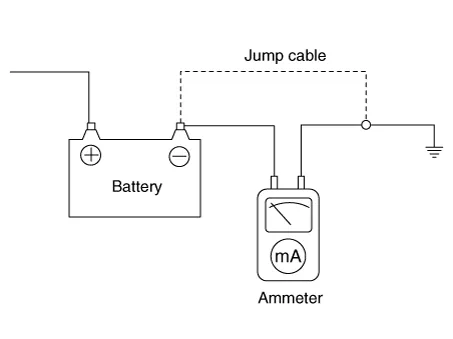

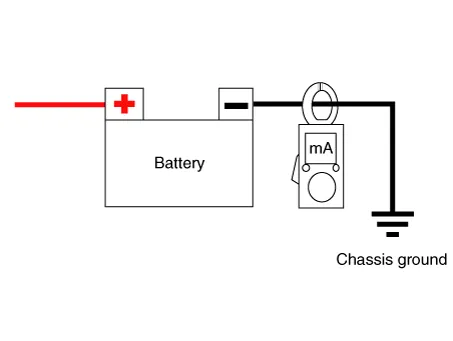

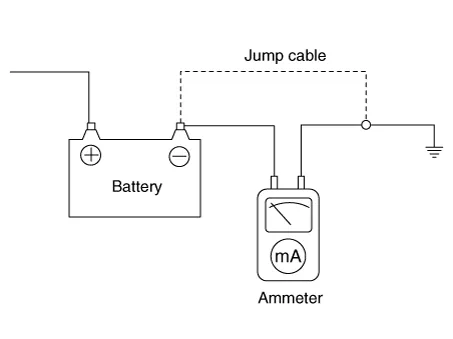

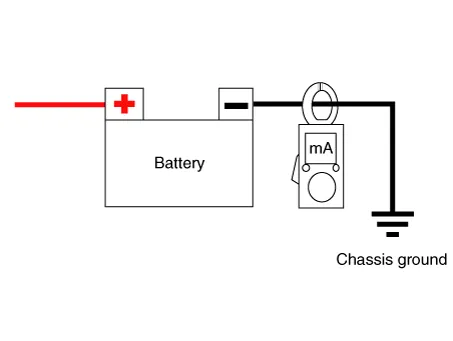

Vehicle parasitic current inspection

[Using an Ammeter]

| 1. | Turn all electric devices OFF, and then turn the ignition switch OFF. |

| 2. | Close all doors except the engine hood, and then lock all doors. | (1) | Disconnect the hood switch connector. |

| (3) | Close the doors or remove the door switches. |

|

| 3. | Wait a few minutes until the vehicle’s electrical systems go to sleep mode. | •

| For

an accurate measurement of a vehicle parasitic current, all electrical

systems should be in sleep mode. (It takes at least one hour or at most

one day.) However, an approximate vehicle parasitic current can be

measured after 10 - 20 minutes. |

|

|

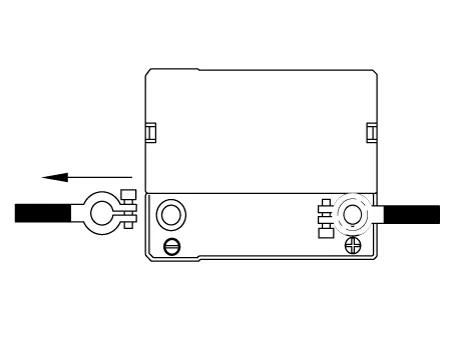

| 4. | Connect

an ammeter in series between the negative (-) battery terminal and the

ground cable, and then slowly disconnect the clamp from the negative (-)

battery terminal. | •

| Make

sure that the lead wires of the ammeter are securely connected to

battery (-) terminal and ground to prevent the battery from being reset.

In case the battery is reset, connect the battery cable again, and then

start the engine or turn the ignition switch ON for more than 10

seconds. Repeat the procedure from No. 1. To prevent the battery from being reset during the inspection, |

| 1) | Connect a jump cable between the battery (-) terminal and the ground cable. |

| 2) | Disconnect the ground cable from the battery (-) terminal. |

| 3) | Connect an ammeter between the battery (-) terminal and the ground cable. |

| 4) | After disconnecting the jump cable, read the current value of the ammeter. |

|

|

| 5. | Read the current value of the ammeter. | •

| If

the parasitic current is over the limit value, search for abnormal

circuit by removing a fuse one by one and checking the parasitic

current. |

| •

| Reconnect

only the fuse suspected of parasitic current and search for the

problematic unit by removing the components connected to the circuit one

by one until the parasitic draw drops below limit value. |

Limit value (after 10 - 20 min.) : Below 50mA |

|

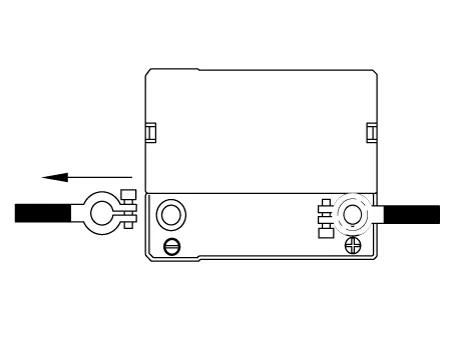

[Using a Clamp type Ammeter]

| 1. | Turn all electric devices OFF, and then turn the ignition switch OFF. |

| 2. | Close all doors except the engine hood, and then lock all doors. | (1) | Disconnect the hood switch connector. |

| (3) | Close the doors or remove the door switches. |

|

| 3. | Wait a few minutes until the vehicle’s electrical systems go to sleep mode. | •

| For

an accurate measurement of a vehicle parasitic current, all electrical

systems should be in sleep mode. (It takes at least one hour or at most

one day.) However, an approximate vehicle parasitic current can be

measured after 10 - 20 minutes. |

|

|

| 4. | Install a clamp type ammeter to negative (-) battery terminal.

|

| 5. | Read the current value of the ammeter. | •

| If

the parasitic current is over the limit value, search for abnormal

circuit by removing a fuse one by one and checking the parasitic

current. |

| •

| Reconnect

only the fuse suspected of parasitic current and search for the

problematic unit by removing the components connected to the circuit one

by one until the parasitic draw drops below limit value. |

Limit value (after 10 - 20 min.) : Below 50mA |

|

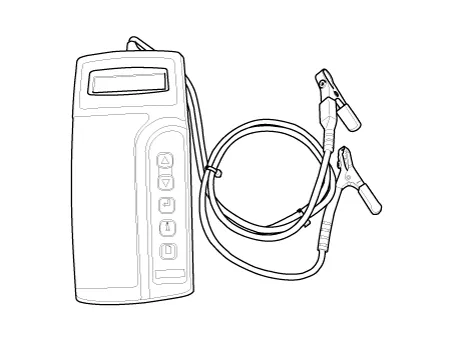

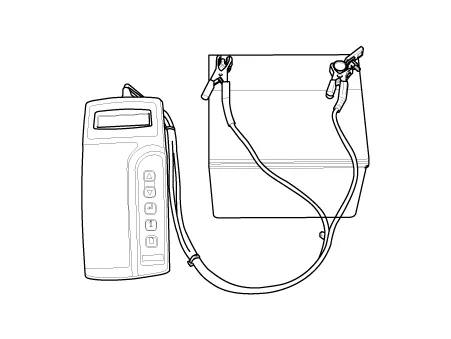

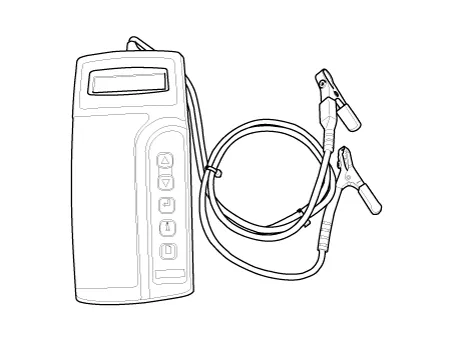

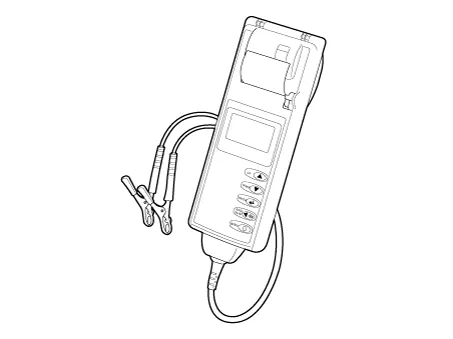

By using the Micro 570 Analyzer, the charging and starting systems including the battery, starter and alternator can be tested.

| •

| Due

to the possibility of personal injury, always take extreme caution and

wear appropriate eye protection when working on batteries. |

| •

| When charging the battery based on test result, it must be fully charged. When

retesting after charging the battery, test after the surface voltage of

the battery have subsided for an accurate test result. (Refer to

"Battery Test Result" below.) |

|

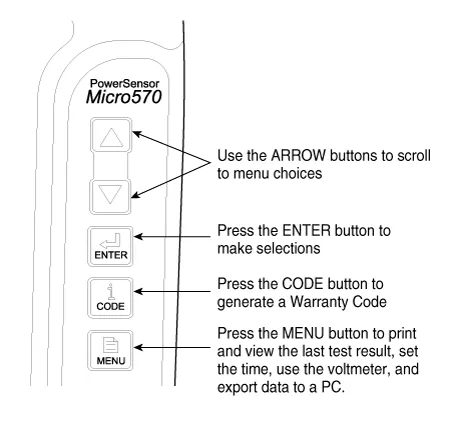

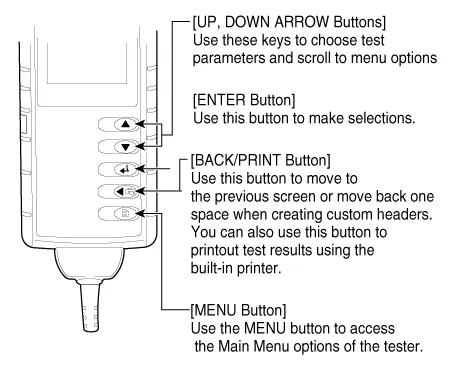

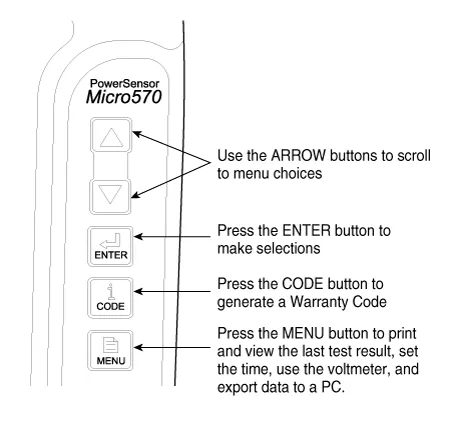

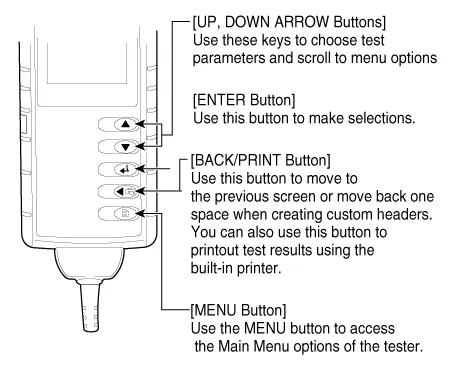

Keypad

The Micro 570 buttons on the keypad provide the following functions:

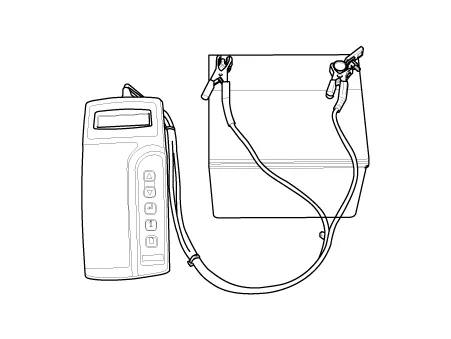

Battery Test Procedure

| 1. | Connect the tester to the battery. | –

| Red clamp to positive (+) battery terminal |

| –

| Black clamp to negative (-) battery terminal |

| •

| Connect clamps securely. If "CHECK CONNECTION" message is displayed on the screen, reconnect clamps securely. |

|

|

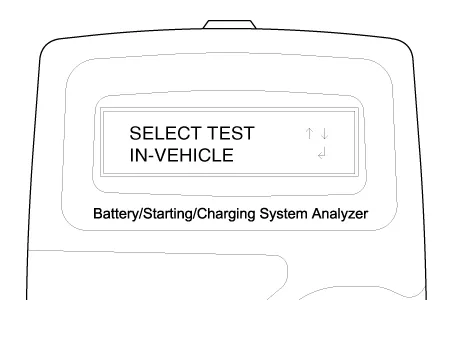

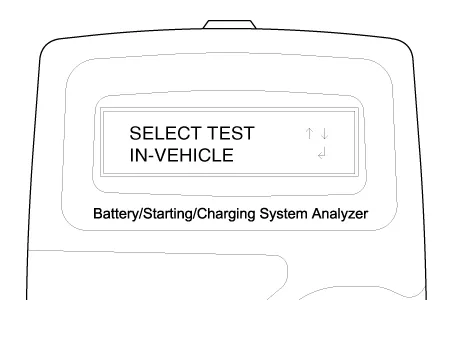

| 2. | The

tester will ask if the battery is connected "IN-VEHICLE" or

"OUT-OF-VEHICLE". Make your selection by pressing the arrow buttons;

then press ENTER.

|

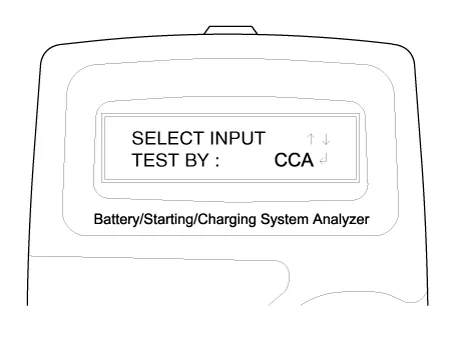

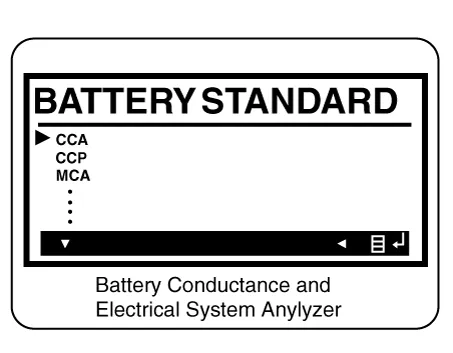

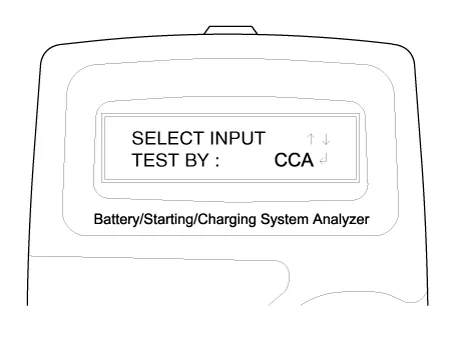

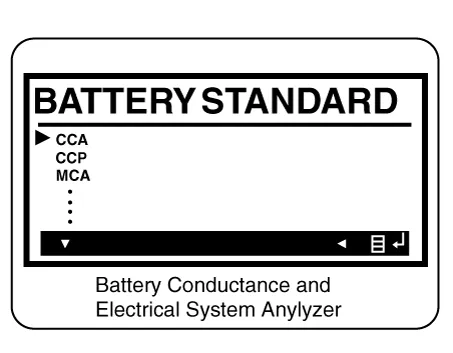

| 3. | Select CCA and press the ENTER button.

| •

| CCA : Cold cranking amps, is an SAE specification for cranking batteries at -0.4°F (-18°C). |

|

|

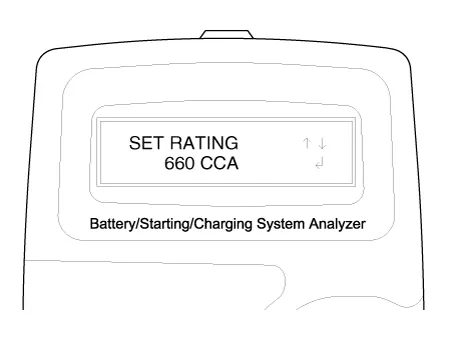

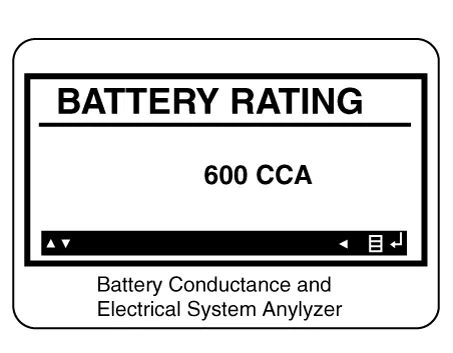

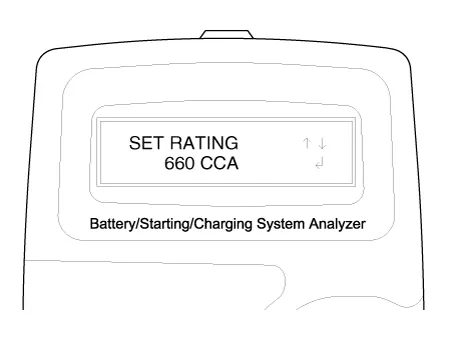

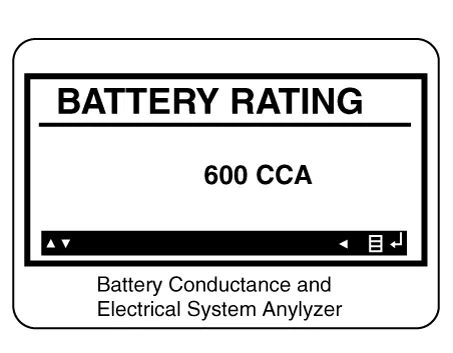

| 4. | Set

the CCA value displayed on the screen to the CCA value marked on the

battery label by pressing up and down buttons and pressing ENTER.

| •

| The battery ratings (CCA) displayed on the tester must be identical to the ratings marked on battery label. |

|

|

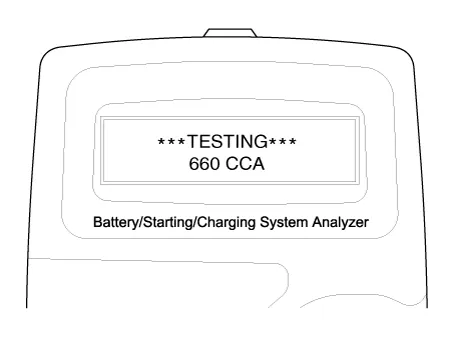

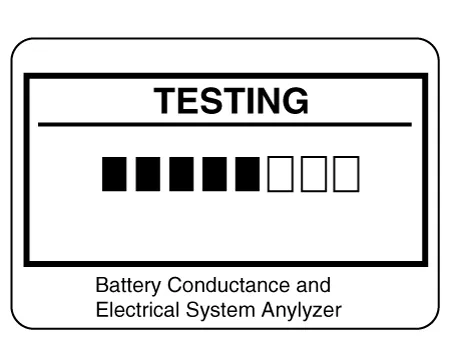

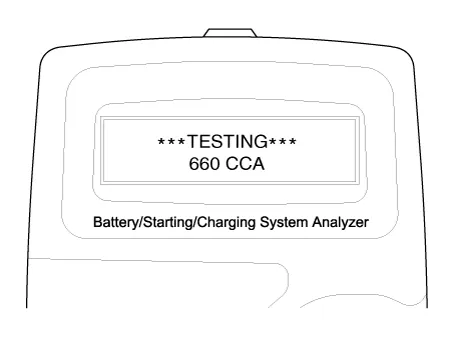

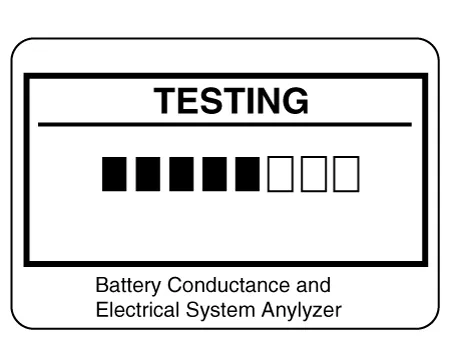

| 5. | The tester will conduct battery test.

|

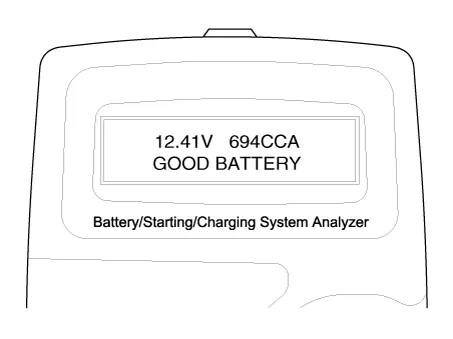

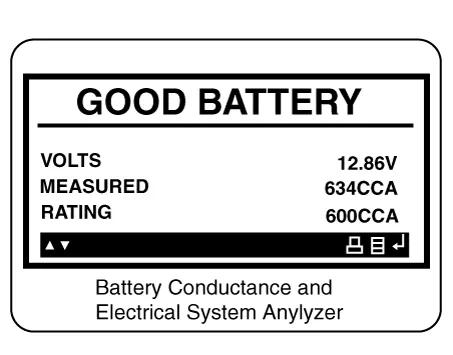

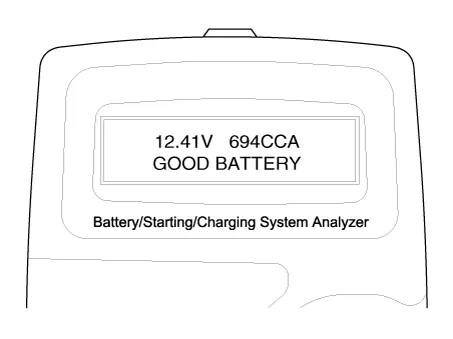

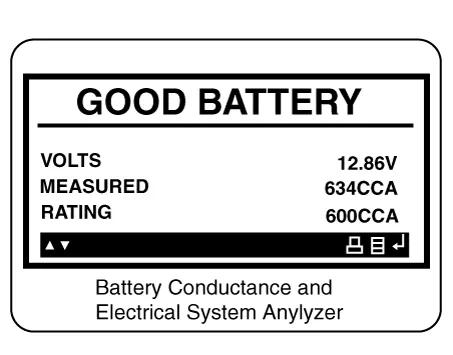

| 6. | The tester displays battery test results including voltage and battery ratings. Refer to the following table and take the appropriate action as recommended by the Micro 570.

Battery Test Results

Result On Printer

|

Remedy

| GOOD BATTERY

| No action is required.

| GOOD - RECHARGE

| Battery is in a good state.

Recharge the battery for use.

| •

| Follow

the instruction below when charging and retesting the battery,

otherwise the test result may be inaccurate. (See ‘Charging and

Retesting after charging battery’ below.) |

| CHARGE & RETEST

| Battery is not charged properly.

| –

| Charge and test the battery again. |

| •

| Follow

the instruction below when charging and retesting the battery,

otherwise the test result may be inaccurate. (See ‘Charging and

Retesting after charging battery’ below.) |

| REPLACE BATTERY

| Replace battery and recheck the charging system.

| –

| Improper

connection between battery and vehicle cables may prompt "REPLACE

BATTERY" message. Retest the battery after removing cables and

connecting the tester to the battery terminal directly prior to

replacing the battery. |

| BAD CELL-REPLACE

| Charge and retest the battery.

| –

| If "REPLACE BATTERY" is prompted on Micro 570, replace the battery and recheck the charging system. |

|

[Charging and Retesting after charging battery]

Charging battery

Set battery charger to ‘Auto Mode’ (the Mode that

charging current drops as the battery charges) and charge battery until

charging current drops down close to zero or the charger alerts with an

alarm when charging is complete. (Minimum charging time recommended: More than 3 hours in Auto Mode explained above) | •

| If

battery is not fully charged, battery surface voltage will be high

while the amount of current charged (CCA) in battery is low. If the

battery is tested in this condition, the tester may misjudge that

battery sulfation has occurred as the level of current in battery is too

low in comparison with battery voltage. * Surface voltage:

When battery is charged, electrolyte temperature increases and chemical

reaction becomes active resulting in an excessive increase in battery

voltage. It is known that it takes approximate one day to subside this increased surface voltage completely. |

Testing battery after charging

Do not test the battery immediately after charging.

Test the battery after the battery surface voltage has subsided as

instructed in the following procedure. | (1) | When battery charging is complete, install the battery to the vehicle. |

| (2) | Turn IG ON, turn on the headlamps at low beam, and wait for 5 minutes. (Discharge for 5 minutes.) |

| (3) | Turn off the headlamps at IG ON, and wait for 5 minutes. (Wait for 5 minutes.) |

| (4) | Remove +, - cables from the battery and test battery. |

| •

| Whenever filing a claim for battery, the print out of the battery test results must be attached. |

|

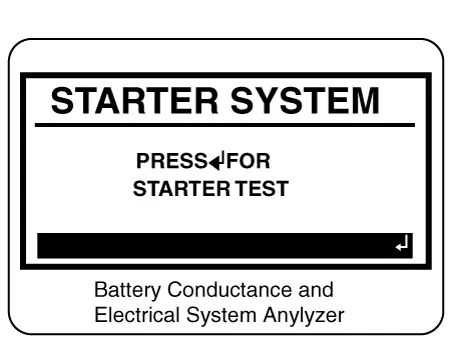

Starter Test Procedure

|

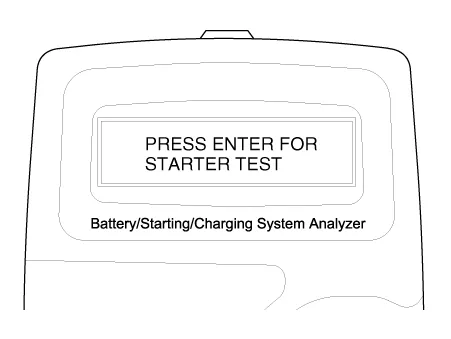

| 7. | After the battery test, press ENTER immediately for the starter test.

|

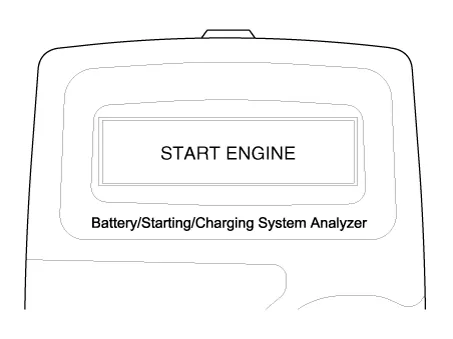

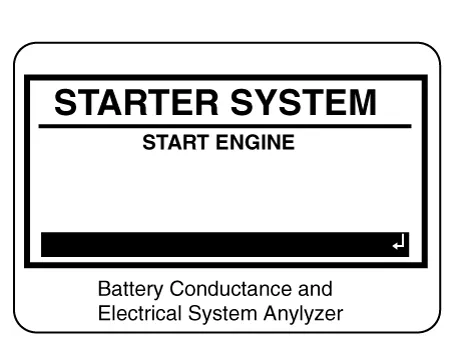

| 8. | Start the engine.

|

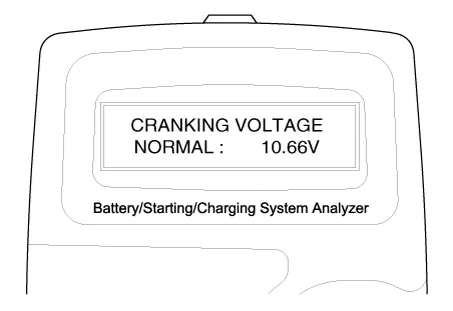

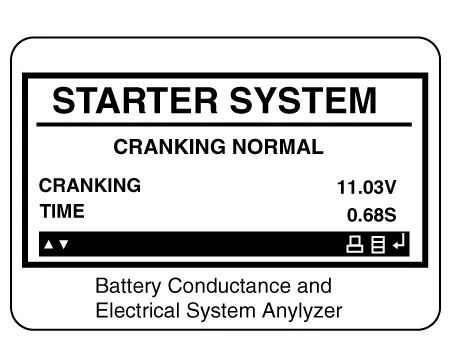

| 9. | Cranking voltage and starter test results will be displayed on the screen. Refer to the following table and take the appropriate action as recommended by the Micro 570.

Starter Test Results

Result On Printer

|

Remedy

| CRANKING VOLTAGE NORMAL

| System shows a normal starter draw.

| CRANKING VOLTAGE LOW

| Cranking voltage is lower than normal level.

| CHARGE BATTERY

| The battery level is too low for the test.

| –

| Charge the battery and retest. |

| REPLACE BATTERY

| Replace battery.

| –

|

If the vehicle cannot be started even though "GOOD BATTERY" is

displayed, check wiring for open circuit, battery cable connection and

starter, and repair or replace as necessary. |

| –

| If the engine does crank, check fuel system. |

|

| •

| When

testing a vehicle with an old diesel engine, the test result may not be

favorable if the glow plug is not heated. Conduct the test after

warming up the engine for 5 minutes. |

|

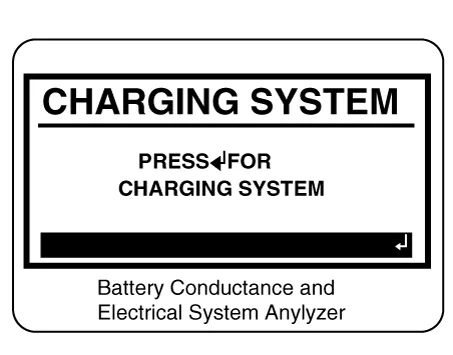

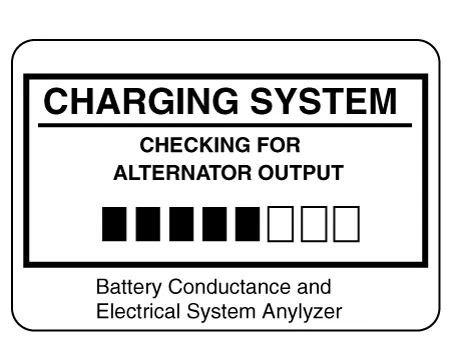

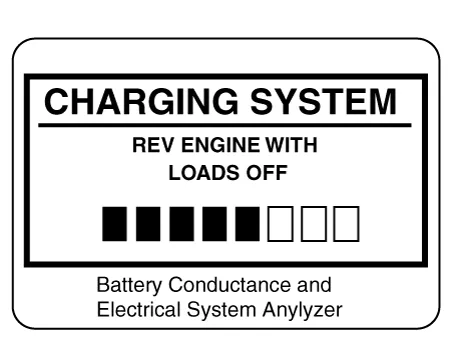

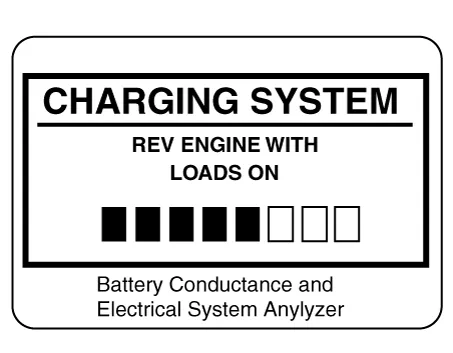

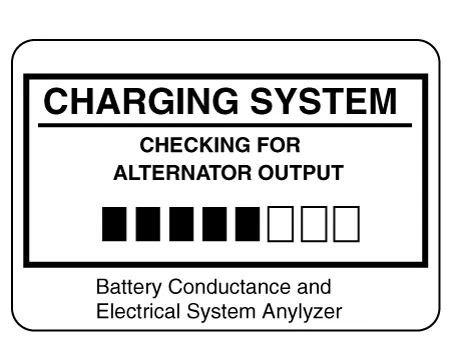

Charging System Test Procedure

|

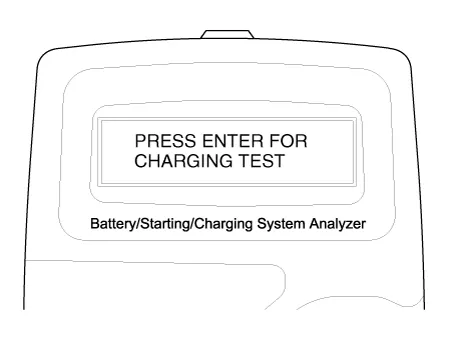

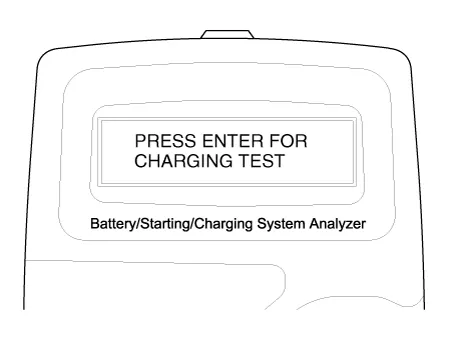

| 10. | Press ENTER to begin charging system test.

|

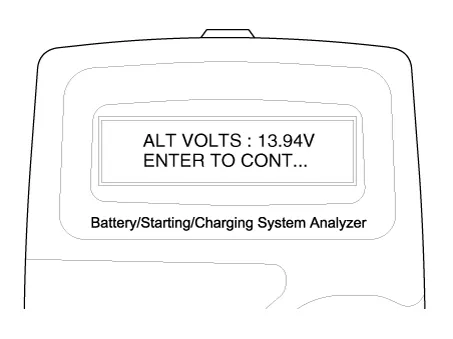

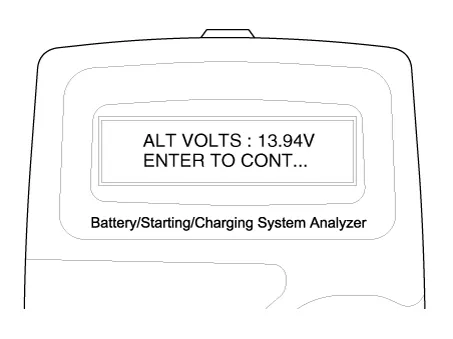

| 11. | The tester displays the actual voltage of alternator. Press ENTER to continue.

|

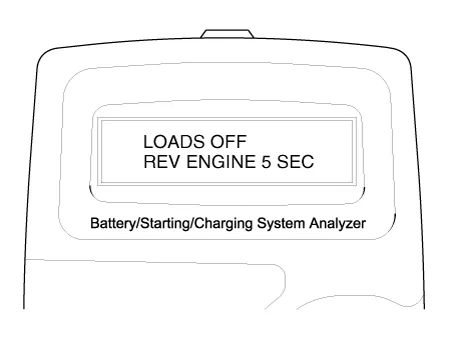

| 12. | Turn

off all electrical loads and rev up the engine for 5 seconds by

pressing the accelerator pedal. (Follow the instructions on the screen)

|

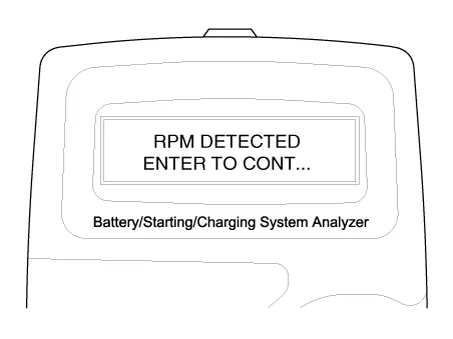

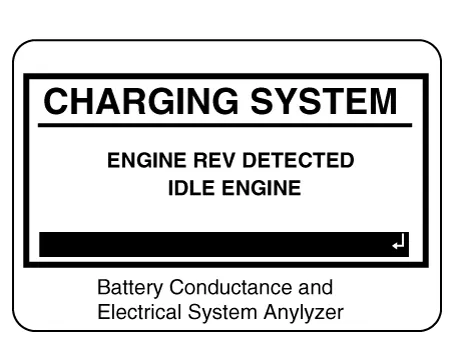

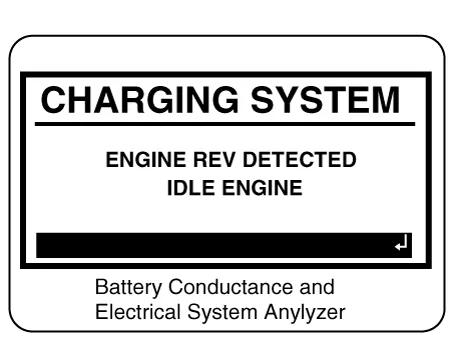

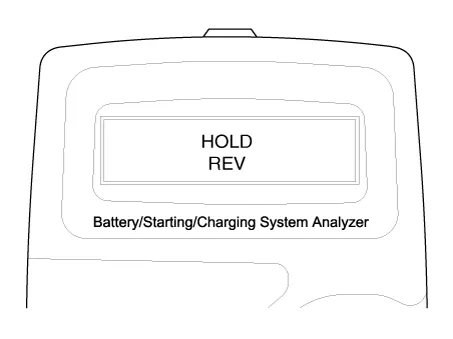

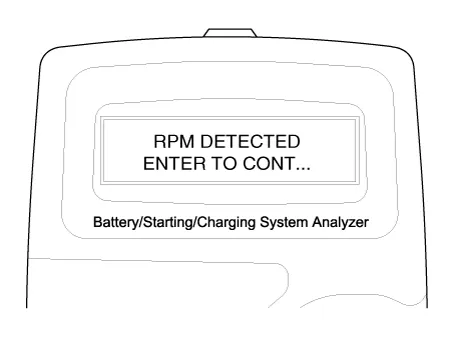

| 13. | The message that engine RPM is detected will be displayed on the screen. Press ENTER to continue.

|

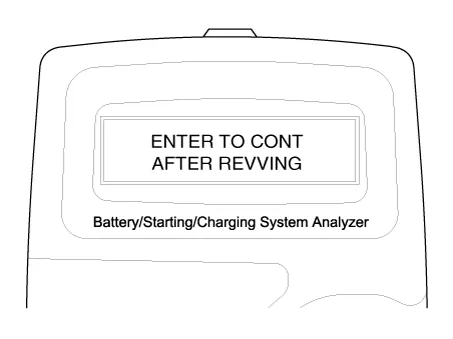

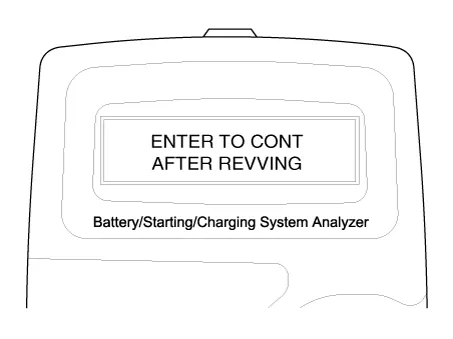

| 14. | If the engine RPM is not detected, press ENTER after revving up the engine.

|

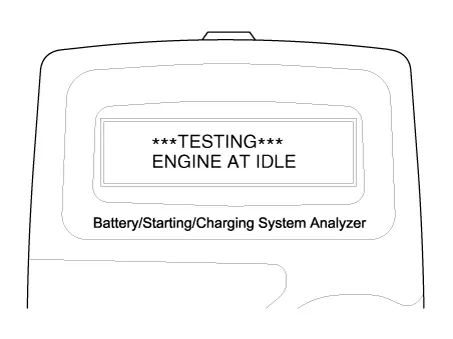

| 15. | The tester will conduct charging system test during loads off.

|

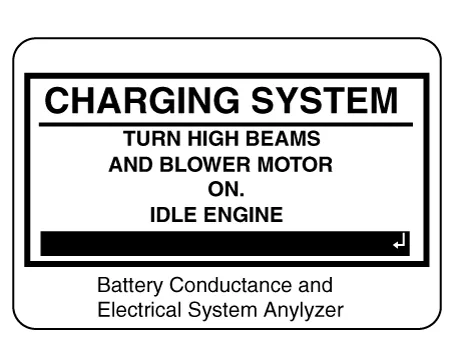

| 16. | Turn on electrical loads (air conditioner, lamps, audio and etc). Press ENTER to continue.

|

| 17. | The tester will conduct charging system test during loads on.

|

| 18. | Rev up the engine for 5 seconds by pressing the accelerator pedal. (Follow the instructions on the screen.)

|

| 19. | The message that engine RPM is detected will be displayed on the screen. Press ENTER to continue.

|

| 20. | If the engine RPM is not detected, press ENTER after revving up the engine.

|

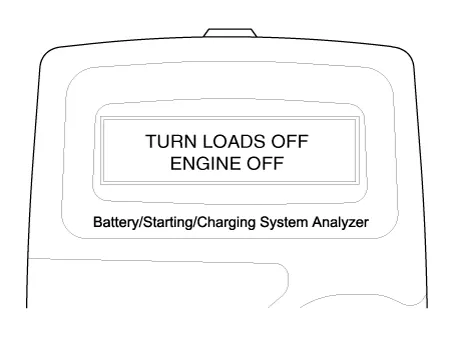

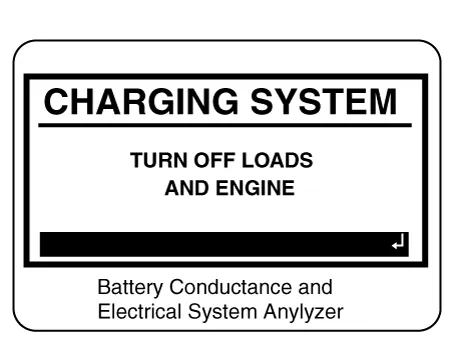

| 21. | Turn off electrical loads (air conditioner, lamps, audio and etc). Turn the engine off.

|

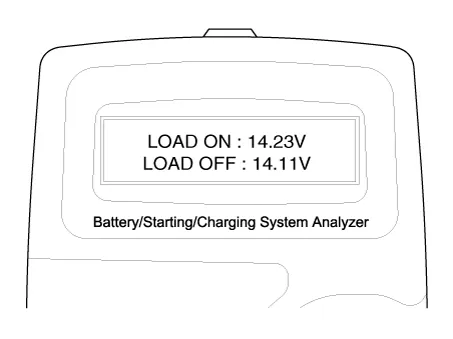

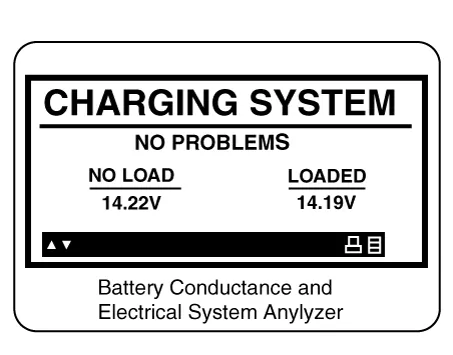

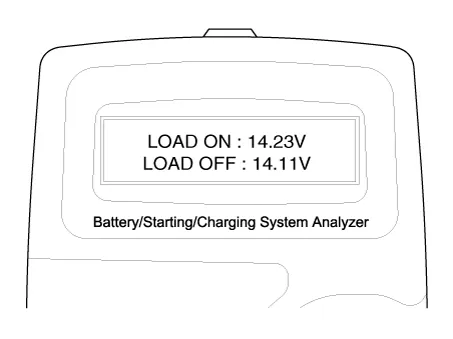

| 22. | Charging voltage and charging system test results will be displayed on the screen. Shut

off the engine and disconnect the tester clamps from the battery. Refer

to the following table and take the appropriate action as recommended

by the Micro 570.

Charging System Test Results

Result On Printer

|

Remedy

| CHARGING SYSTEM NORMAL / DIODE RIPPLE NORMAL

| Charging system is normal.

| NO CHARGING VOLTAGE

| Alternator does not supply charging current to battery.

| –

| Check belts, connection between alternator and battery and replace belts, cable or alternator as necessary. |

| LOW CHARGING VOLTAGE

| Alternator does not supply charging current to battery and electrical load to system fully.

| –

| Check belts and alternator and replace as necessary. |

| HIGH CHARGING VOLTAGE

| The voltage from alternator to battery is higher than normal limit during voltage regulation.

| –

| Check connection and ground and replace regulator as necessary. |

| –

| Check electrolyte level in the battery. |

| EXCESS RIPPLE DETECTED

| One or more diodes in the alternator is not functioning properly.

| –

| Check alternator mounting and belts and replace as necessary. |

|

|

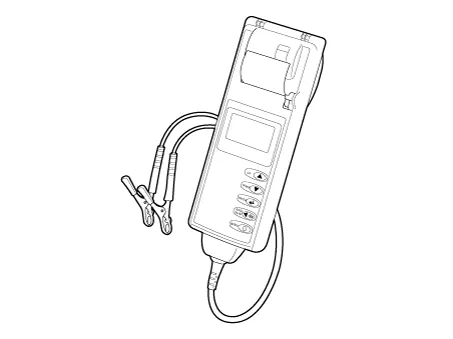

The MDX-670P Analyzer

The

MDX-670P battery conductance and electrical system analyzer tests

batteries as well as starting and charging systems of the vehicle.

It displays the test results in seconds and features a built-in printer to provide a copy of the results.

| 1) | Due

to the possibility of personal injury, always take extreme caution and

wear appropriate eye protection when working on batteries. |

| 2) | When

charging a battery based on test result, it must be fully charged. For

an accurate test result, test the battery when the battery surface

voltage has subsided completely after charging it. (Refer to Battery

Test Results below.) |

|

| •

| When

testing a vehicle with an old diesel engine, the test result may not be

favorable if the glow plug is not heated. Conduct the test after

warming up the engine for 5 minutes. |

|

| 1. | Connect the red clamp to the positive (+) terminal and the black clamp to the negative (–) terminal. | •

| For

a proper connection, rock the clamps back and forth. The tester

requires that both sides of each clamp be firmly connected before

testing. A poor connection may prompt CHECK CONNECTION or WIGGLE CLAMPS

message. If the message appears, clean the terminals and reconnect the

clamps. |

|

|

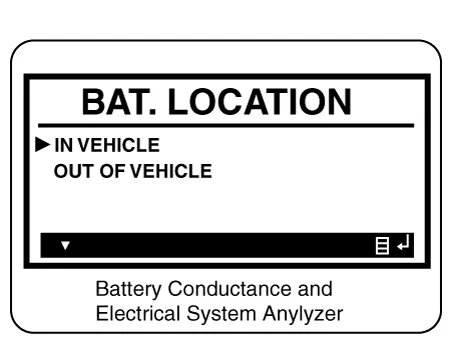

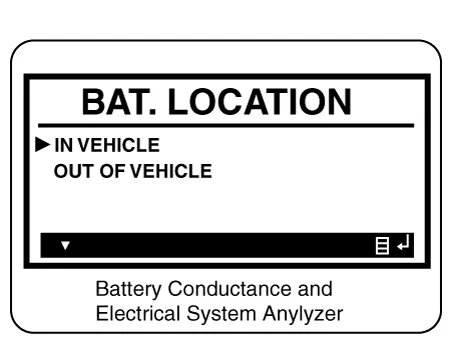

| 2. | Scroll to and select IN VEHICLE or OUT OF VEHICLE for a battery not connected to a vehicle.

| •

| For a vehicle equipped with ISG function, select the AGM FLAT PLATE. |

|

|

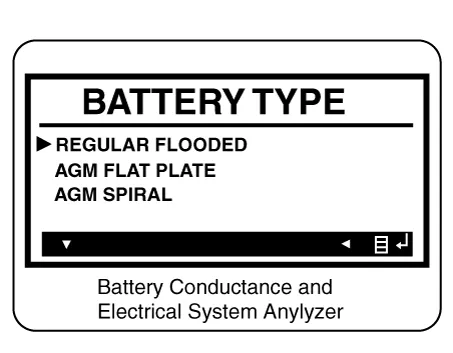

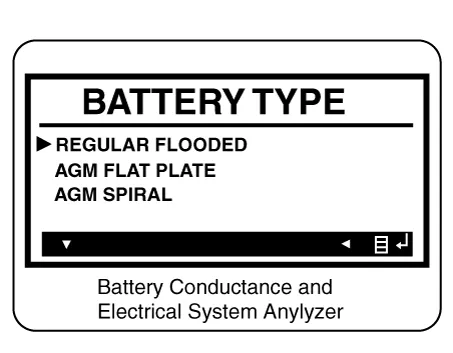

| 3. | Scroll to and select REGULAR FLOODED, AGM FLAT PLATE, or AGM SPIRAL where applicable.

| •

| If the vehicle equipped with ISG function, select the AGM FLAT PLATE. |

|

|

| 4. | Scroll to and select the battery’s rating system. | •

| In

most cases, the CCA value is marked on the battery label, but sometimes

it is substituted with the EN or SEA value. Select any of them. |

|

| –

| CCA: Cold Cranking Amps, as specified by SAE, is the most common rating for cranking batteries at 0°F (-17.8°C). |

| –

| SAE: Society of Automotive Engineers, the European labeling of CCA |

|

| 5. | Set

the selected rating value displayed on the screen to the value marked

on the battery label by pressing up and down arrow buttons.

|

| 6. | Press ENTER to start test.

|

| 7. | After

several seconds, the tester will display the battery condition and the

measured voltage. The tester will also display the battery rating and

the rating units.

Battery Test Results

Result On Printer

|

Remedy

| GOOD - RECHARGE

| No action is required.

| GOOD RECHARGE

| Battery is in a good state. Recharge the battery for use.

| •

| Follow

the instruction below when charging and retesting the battery,

otherwise the test result may be inaccurate. (See ‘Charging and

Retesting after charging battery’ below.) |

| CHARGE & RETEST

| Battery is not charged properly.

| –

| Charge and test the battery again. |

| •

| Follow

the instruction below when charging and retesting the battery,

otherwise the test result may be inaccurate. (See ‘Charging and

Retesting after charging battery’ below.) |

| REPLACE BATTERY

| Replace battery and recheck the charging system.

| –

| Improper

connection between battery and vehicle cables may prompt "REPLACE

BATTERY" message. Retest the battery after removing cables and

connecting the tester to the battery terminal directly prior to

replacing the battery. |

| BAD CELL - REPLACE

| Charge and retest the battery.

| –

| If "REPLACE BATTERY" is prompted on MDX-670P Analyzer, replace the battery and recheck the charging system. |

|

[Charging and Retesting after charging battery]

Charging battery

Set battery charger to ‘Auto Mode’ (the Mode that

charging current drops as the battery charges) and charge battery until

charging current drops down close to zero or the charger alerts with an

alarm when charging is complete. (Minimum charging time recommended:

More than 3 hours in Auto Mode explained above) | •

| If

battery is not fully charged, battery surface voltage will be high

while the amount of current charged (CCA) in battery is low. If the

battery is tested in this condition, the tester may misjudge that

battery sulfation has occurred as the level of current in battery is too

low in comparison with battery voltage. * Surface voltage:

When battery is charged, electrolyte temperature increases and chemical

reaction becomes active resulting in an excessive increase in battery

voltage. It is known that it takes approximate one day to subside this increased surface voltage completely. |

Testing battery after charging

Do not test the battery immediately after charging.

Test the battery after the battery surface voltage has subsided as

instructed in the following procedure. | (1) | When battery charging is complete, install the battery to the vehicle. |

| (2) | Turn IG ON, turn on the headlamps at low beam, and wait for 5 minutes. (Discharge for 5 minutes.) |

| (3) | Turn off the headlamps at IG ON, and wait for 5 minutes. (Wait for 5 minutes.) |

| (4) | Remove +, - cables from the battery and test battery. |

| •

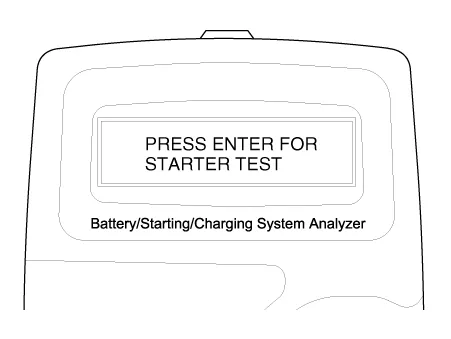

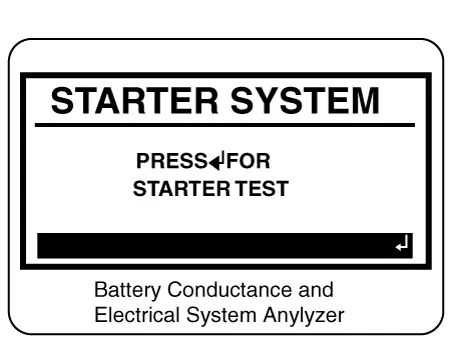

| For an in-vehicle test, the display alternates between the test results and the message “PRESS FOR STARTER TEST. |

|

| •

| Before

starting the test, inspect the alternator drive belt. A belt that is

glazed or worn, or lacks the proper tension, will prevent the engine

from achieving the rpm levels needed for the test. |

|

|

| 8. | Press the ENTER button to proceed with the starter test.

|

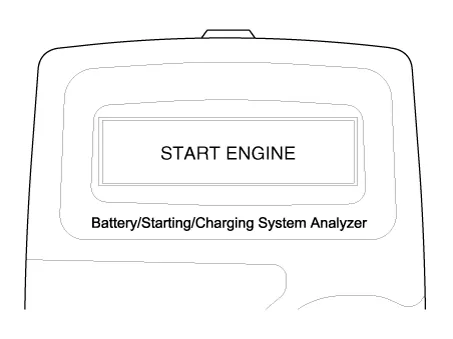

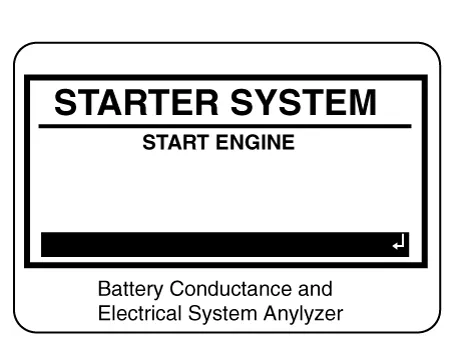

| 9. | Start the engine when prompted.

|

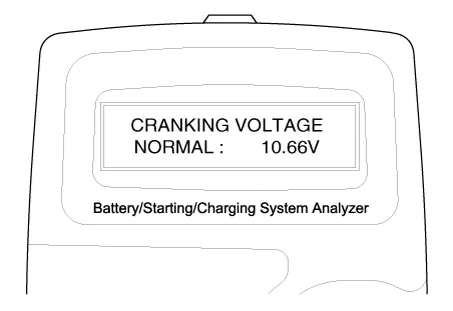

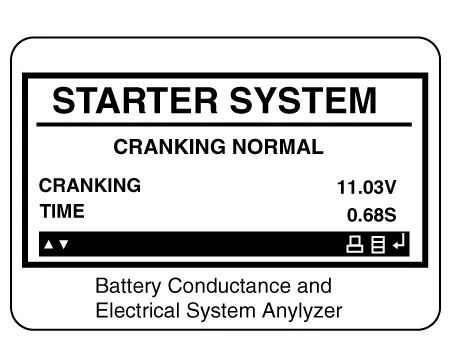

| 10. | The tester displays the status of the starter system, cranking voltage, and cranking time in milliseconds.

Starter Test Results

Result On Printer

|

Remedy

| CRANKING VOLTAGE NORMAL

| System shows a normal starter draw.

| CRANKING VOLTAGE LOW

| Cranking voltage is lower than normal level.

| CHARGE BATTERY

| The battery level is too low for the test.

| –

| Charge the battery and retest. |

| REPLACE BATTERY

| Replace battery.

| –

|

If the vehicle cannot be started even though "GOOD BATTERY" is

displayed, check wiring for open circuit, battery cable connection and

starter, and repair or replace as necessary. |

| –

| If the engine does not crank, check fuel system. |

|

| •

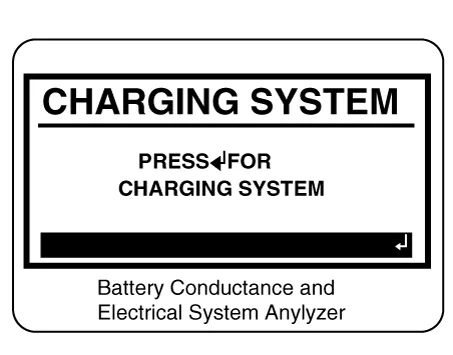

| For an in-vehicle test, the display alternates between the test results and the message “PRESS FOR CHARGING TEST. |

|

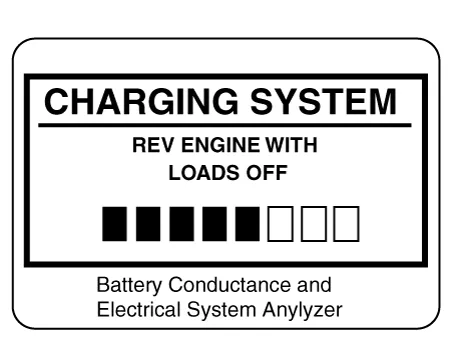

Step 3: Charging System Test

|

| 11. | Press the ENTER button to proceed with the charging test.

|

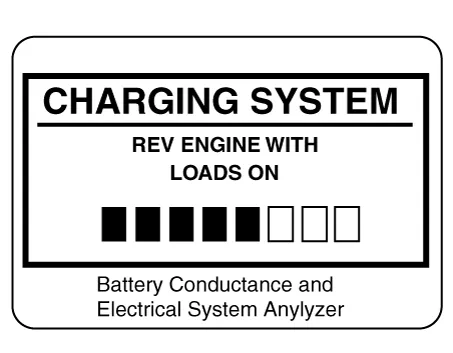

| 12. | Rev up the engine with loads off. (Following the on-screen prompts)

|

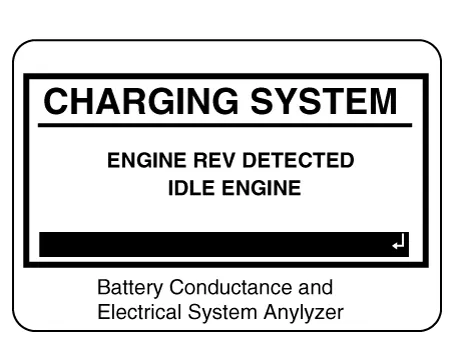

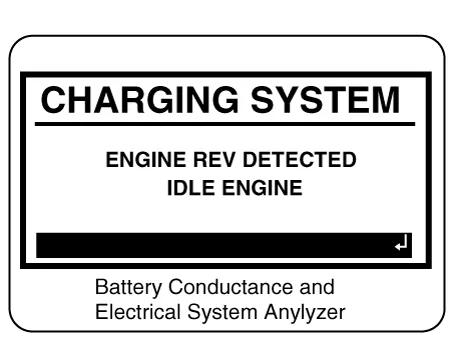

| 13. | The message that engine RPM is detected will be displayed on the screen. Idle the engine.

|

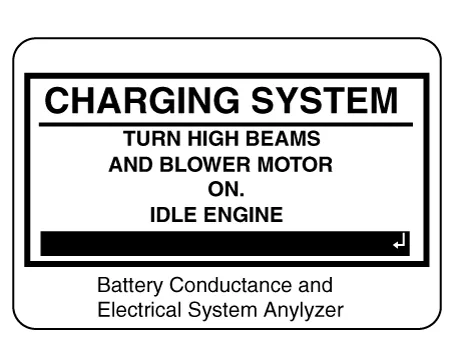

| 14. | Turn on electrical loads (air conditioner, lamps, audio and etc). Press ENTER to continue.

|

| 15. | Rev up the engine with the electrical loads on.

|

| 16. | The message that engine RPM is detected will be displayed on the screen. Idle the engine.

|

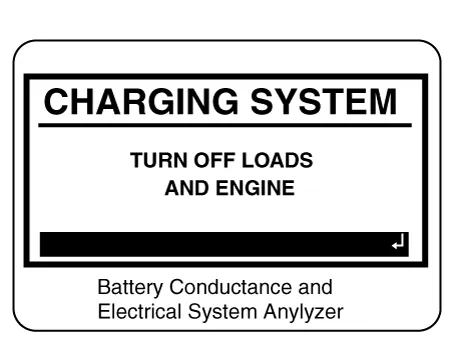

| 17. | Turn off loads and engine.

|

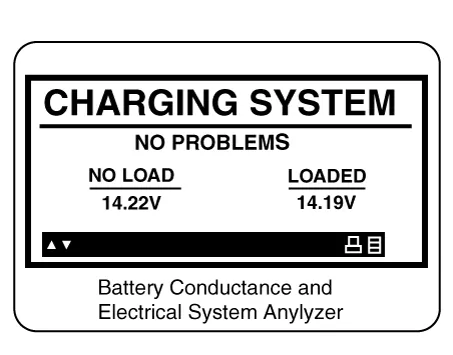

| 18. | The status of the Charging System is displayed at the end of the procedure.

Result On Printer

|

Remedy

| NO PROBLEMS

| System is showing normal output from the alternator.

| NO OUTPUT

| No alternator output detected.

| –

| Check

all connections to and from the alternator, especially the connection

to the battery. If the connection is loose or heavily corroded, clean or

replace the cable and retest. |

| –

| If

the belts and connections are in good working condition, replace the

alternator. (Older vehicles use external voltage regulators, which may

require replacement of the voltage regulator only.) |

| LOW OUTPUT

| Alternator does not supply charging current to battery and electrical load to system fully.

| –

| Check belts and alternator and replace as necessary. |

| HIGH OUTPUT

| The voltage from alternator to battery is higher than normal limit during voltage regulation.

| –

| Check connection and ground and replace regulator as necessary. |

| –

| Check electrolyte level in the battery. |

| EXCESSIVE RIPPLE

| The voltage from alternator to battery is higher than normal limit during voltage regulation.

| –

| Check alternator mounting and belts and replace as necessary. |

| CHARGE BATTERY

| The starter voltage is low and the battery is discharged. Fully charge the battery and repeat the starter system test.

| REPLACE BATTERY

| Battery must be replaced before the starting system can be tested.

|

|

| 19. | Press the BACK/PRINT button to print the test results or MENU to return to the Options Menu. |

| 1. | Make sure that the ignition switch and all accessories are turned OFF. |

| 2. | Disconnect the battery cables (negative first). |

| 3. | Remove the battery from the vehicle. | •

| Care should be taken in the event the battery case is cracked or leaking, to protect your skin from the electrolyte. Heavy duty rubber gloves (not the household type) should be worn when removing the battery. |

|

|

| 4. | Inspect

the battery tray for damage caused by the loss of electrolyte. If acid

damage is present, it will benecessary to clean the are a with a

solution of clean warm water and baking soda. Scrub the area with a

stiff brush and wipe off with a cloth moistened with baking soda and

water |

| 5. | Clean the top of the battery with the same solution as described above. |

| 6. | Inspect the battery case and cover for cracks. If cracks are present, the battery must be replaced. |

| 7. | Clean the battery posts with a suitable battery post tool. |

| 8. | Clean

the inside surface of the terminal clamps with a suitable battery

cleaning tool. Replace damaged or frayed cables and broken terminal

clamps. |

| 9. | Install the battery in the vehicle. |

| 10. | Connect the cable terminals to the battery post, making sure tops of the terminals are flush with the tops of the posts . |

| 11. | Tighten the terminal nuts securely. |

| 12. | Coat all connections with light mineral grease after tightening. | •

| When

batteries are being charged, an explosive gas forms beneath the cover

of each cell. Do not smoke near batteries being charged or

which have recently been charged. Do not break live circuit at the

terminals of batteries being charged. A spark will occur when the circuit is broken. Keep open flames away from battery. |

|

|

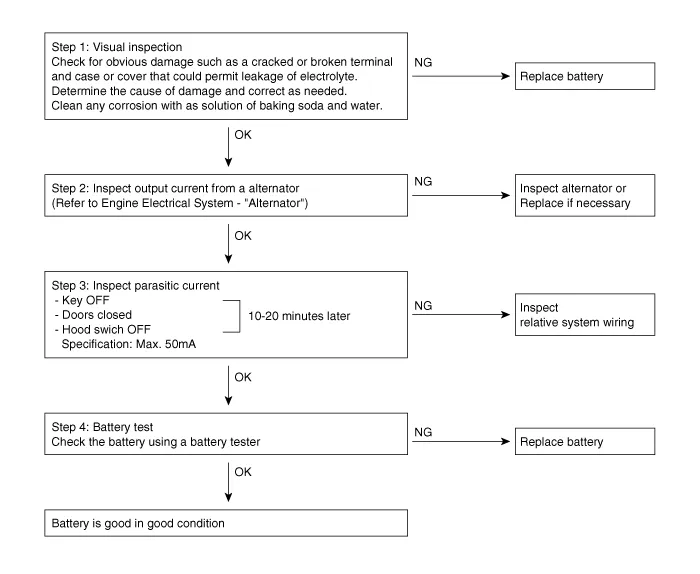

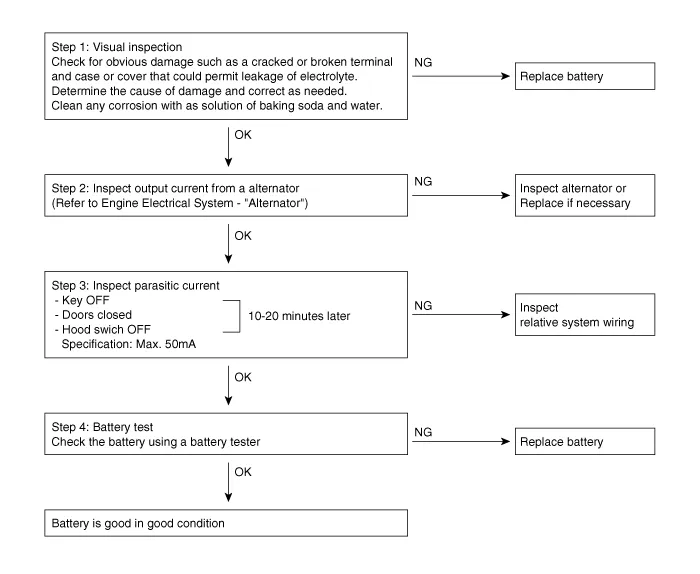

Troubleshooting

Description and operation

Description

In

order to ensure adequate brake power assistance in every situation, the

brake booster is equipped with a partial vacuum sensor.

Description and operation

Description

Due

to the considerably more frequent occurrence of starting operations,

the electrical load that occurs often leads to voltage dips in the

vehicle network.

Other information:

Schematic diagrams

Circuit Diaram

Description and operation

Description

The

immobilizer system will disable the vehicle unless the proper ignition

key is used, in addition to the currently available anti-theft systems

such as car alarms, the immobilizer system aims to drastically reduce

the rate of auto theft.

Components and components location

Components

Driver Power Window Switch

Connector Pin Information

[All Manual / Auto Down Type]

(LHD)

No.

Description

No.