Kia Picanto (JA): Clutch System / Clutch Release Fork and Clutch Release Bearing

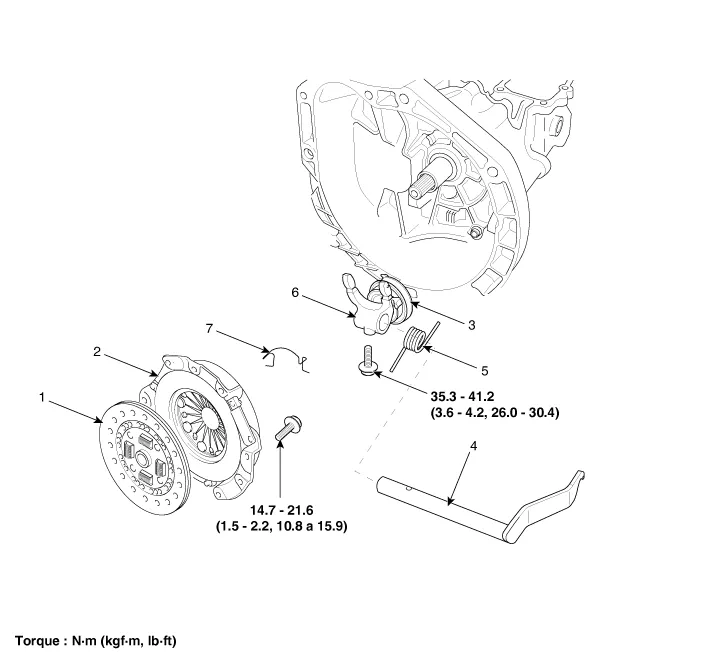

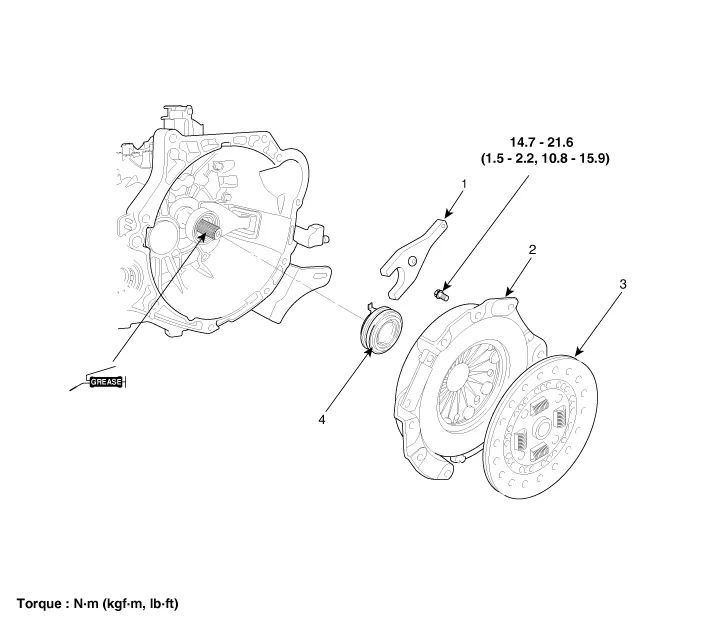

Components and components location

| Components |

| 1. Clutch disc assembly 2. Clutch cover assembly 3. Clutch release bearing 4. Clutch release lever assembly | 5. Return spring 6. Clutch release fork 7. Return clip |

| 1. Clutch release fork 2. Clutch cover assembly | 3. Clutch disk assembly 4. Clutch release bearing |

Repair procedures

| Removal |

| 1. | Remove the transaxle assembly.

G 1.0 MPI KAPPA (Refer to Manual Transaxle System - "Manual Transaxle")

G 1.2 MPI KAPPA (Refer to Manual Transaxle System - "Manual Transaxle")

F 1.0 KAPPA FFV (Refer to Manual Transaxle System - "Manual Transaxle")

|

| 2. | Remove the reamer bolt.

|

| 3. | Remove the return clip (A) from the release bearing and then remove the release fork and release bearing.

|

| 1. | Remove the transaxle assembly.

G 1.0 T-GDI KAPPA (Refer to Manual Transaxle System - "Manual Transaxle")

|

| 2. | Remove the clutch release bearing (A).

|

| 3. | Pull the clip (A).

|

| 4. | Remove the clutch release fork (A).

|

| 5. | Remove the boot (A).

|

| Installation |

| 1. | Apply multi purpose grease to release fork assembly.

|

| 2. | Apply multi purpose grease into the groove of the release bearing.

|

| 3. | Install the release bearing and release fork to clutch housing.

|

| 4. | Install the reamer bolt.

|

| 5. | Apply multi purpose grease to on contact surface of lever (A).

|

| 6. |

Clean the surfaces of the flywheel and pressure plate throughly with

fine sandpaper or crocus cloth, and make certain that all oil or grease

has been removed. |

| 7. | Apply a small amount of multi purpose grease to the input shaft splines (A).

|

| 8. | Clean

the surfaces of the flywheel and pressure plate thoroughly with fine

sandpaper or crocus cloth, and make certain that all oil or grease has

been removed. |

| 9. | Install the transaxle assembly.

G 1.0 MPI KAPPA (Refer to Manual Transaxle System - "Manual Transaxle")

G 1.2 MPI KAPPA (Refer to Manual Transaxle System - "Manual Transaxle")

F 1.0 KAPPA FFV (Refer to Manual Transaxle System - "Manual Transaxle")

|

| 1. | Install the boot (A).

|

| 2. | Install the clip to the clutch release fork. |

| 3. | Apply to grease in location A, B and C.

|

| 4. | Apply the grease to the hole surface of the clutch release bearing all around.

|

| 5. | Install the clutch release fork (B), clutch release bearing (A).

|

| 6. | Install the transaxle assembly.

G 1.0 T-GDI KAPPA (Refer to Manual Transaxle System - "Manual Transaxle")

|

Repair procedures Removal [Kappa 1.0 T-GDI] 1.Remove the engine room under cover. G 1.0 T-GDI KAPPA (Refer to Engine Mechanical System - "Engine Room Under Cover") 2.

Specifications Specifications Transaxle model M5CF1-1 Engine type Gasoline 1.0 T-GDI Manual transalxe oil Capacity 1.

Other information:

Kia Picanto (JA) 2017-2026 Service & Repair Manual: Seat Heater Switch

Components and components location Components 1. Driver side seat heater switch 2. Passenger side seat heater switch Schematic diagrams Circuit Diagram Repair procedures Removal 1. Disconnect the negative (-) battery terminal.

Kia Picanto (JA) 2017-2026 Service & Repair Manual: Sunroof Motor

Repair procedures Inspection 1.Disconnect the negative (-) battery terminal. 2.Remove the roof trim assembly. (Refer to Body - "Roof Trim Assembly") 3.Remove the glass motor (A) after loosening the mounting screws. 4.

Categories

- Manuals Home

- Kia Picanto Owners Manual

- Kia Picanto Service Manual

- Clutch Cable

- Engine Mechanical System

- Thermostat

- New on site

- Most important about car